From Garden to Garage: Selecting the Ideal Outdoor Ethernet Cable for Your Needs

Extending your network outdoors requires the right Ethernet cable. Standard indoor cables are unsuitable for outdoor environments due to their vulnerability to temperature fluctuations, moisture, UV radiation, and physical damage. Using them outdoors can lead to frequent failures and connectivity problems.

Outdoor Ethernet cables are specifically designed to withstand these challenges. When choosing a cable, consider the environmental conditions and your performance needs.

Table of Contents

Understanding Outdoor Ethernet Cable Requirements

Outdoor networking environments present challenges absent in indoor settings. Consequently, selecting Ethernet cable for outdoor use requires consideration of environmental factors affecting performance and longevity

Standard indoor Ethernet cables are designed for stable, controlled environments with consistent temperatures, no moisture exposure, and protection from physical damage. Outdoor environments expose cables to a range of elements that can degrade their performance and physical integrity.

Outdoor Ethernet cables must be capable of withstanding rain, snow, and high humidity without moisture ingress. They also need to function reliably across a wide temperature range, including extreme heat and freezing conditions. Furthermore, resistance to ultraviolet (UV) radiation from sunlight is necessary to prevent material breakdown. Physical threats from wildlife, landscaping equipment, and wind-induced stress can also damage improperly protected cables.

Specialised outdoor Ethernet cables are engineered with features to address these specific environmental challenges, ensuring stable network operation.

Common Applications for Outdoor Ethernet Cables

Here are some common scenarios where outdoor Ethernet cables are recommended as part of the setup:

Home Security Systems

Modern security systems often incorporate multiple IP cameras, doorbell cameras, and motion sensors around a property. While wireless options exist, hardwired Ethernet connections provide superior reliability and consistent performance without the bandwidth limitations or interference issues common with Wi-Fi. Outdoor-rated Ethernet cables ensure these critical security devices maintain constant connectivity regardless of weather conditions.

Detached Structures

Extending network connectivity to detached garages, workshops, garden sheds, or pool houses is one of the most common uses for outdoor Ethernet cables. Ethernet cables help to enable Internet access and smart home control systems in these secondary spaces. The distance between buildings often makes wired connections more reliable than attempting to extend Wi-Fi coverage, particularly if there are metal structures that can block wireless signals.

Outdoor Entertainment Areas

Patios, decks, and outdoor kitchens increasingly feature smart TVs, audio systems, and other entertainment devices that benefit from stable network connections. Outdoor Ethernet cables can provide the bandwidth needed for streaming 4K content or hosting multiple devices simultaneously without the performance degradation common with wireless connections at longer ranges.

Smart Landscape Features

From automated irrigation systems and garden lighting to weather stations and pool controllers, smart landscape features often perform better with hardwired connections. These devices may be distributed across large areas where wireless signals struggle to reach, making outdoor Ethernet cables the ideal connectivity solution.

Temporary Event Setups

Outdoor events like weddings, concerts, or corporate gatherings often require temporary but reliable network infrastructure. Outdoor-rated Ethernet cables can be deployed to connect point-of-sale systems, live streaming equipment, or guest Wi-Fi access points, ensuring consistent performance throughout the event.

Industrial and Commercial Applications

Beyond residential uses, outdoor Ethernet cables are essential for commercial applications like connecting warehouse buildings, linking retail locations in shopping centers, or establishing connectivity for outdoor industrial equipment. These applications often require higher-category cables with superior shielding due to the presence of industrial equipment and longer cable runs.

Types of Ethernet Cables for Outdoor Use

There are several different categories of Ethernet cables and they differ in their performance. Here’s a brief explanation of the different categories and if you’re interested about finding out more, you can check out our article on what ethernet cable to buy.

Cat5e Cables

Cat5e supports up to 1 Gbps speeds over 100 meters with 100 MHz bandwidth. It is suitable for basic outdoor networking like security cameras, and is the most cost-effective option. However, it has lower bandwidth and less protection against interference, making it potentially less future-proof.

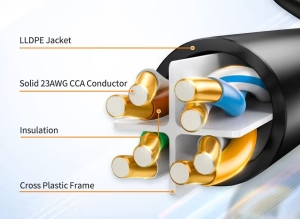

Cat6 Cables

Cat6 offers the same 1 Gbps speed over 100 meters as Cat5e, but can also support 10 Gbps up to 55 meters. Bandwidth is increased to 250 MHz. Cat6 provides a good balance of performance and cost for most residential and small business outdoor needs, offering better shielding and insulation than Cat5e.

Cat6a Cables

Cat6a maintains 10 Gbps speeds over a full 100 meters with 500 MHz bandwidth. Offers significant future-proofing and more robust shielding, making it ideal for high-performance business or prosumer applications and environments with potential electromagnetic interference.

Cat7 Cables

Cat7 provides up to 600 MHz bandwidth and supports 10 Gbps over 100 meters (some variants up to 40 Gbps over shorter distances). It is always fully shielded, offering superior EMI protection. While the premium option, the performance benefits over Cat6a may not justify the higher cost for most residential uses.

Key Features to Look for in Outdoor Ethernet Cables

Weather-Resistant Jacketing

The outer jacket of an Ethernet cable provides the primary environmental protection. Standard indoor cables use PVC jacketing, which degrades rapidly outdoors, potentially leading to cable failure.

Outdoor Ethernet cables utilise materials such as polyethylene (PE) that resist moisture ingress and UV degradation. Inadequate weather resistance allows moisture to penetrate the cable, causing signal degradation, short circuits, and eventual network failure. Jacket deterioration also exposes internal wiring to damage, creating safety and performance issues.

Certain outdoor cables feature double jacketing for enhanced protection. Water-blocking technologies, like gel fillings or tape, prevent moisture migration within the cable if the outer jacket is breached, which is important for maintaining network integrity during severe weather.

When selecting an outdoor Ethernet cable, confirm that it is explicitly designated for outdoor use and specifies its weather resistance and UV protection properties. Cables described merely as “durable” or “heavy-duty” may not offer sufficient outdoor protection.

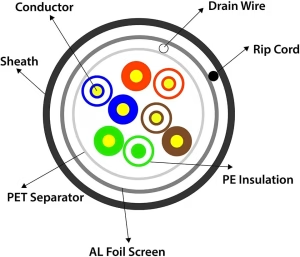

Shielding Options

Outdoor environments typically present higher levels of electromagnetic interference (EMI) compared to controlled indoor settings. Sources such as power lines, electrical equipment, radio transmitters, and atmospheric conditions can generate interference that degrades network performance.

Without adequate shielding, outdoor Ethernet cables may experience increased packet loss, intermittent disconnections, and a reduced effective range. In significant cases, excessive interference can prevent network connections.

Various shielding configurations are available, each providing different levels of interference protection.

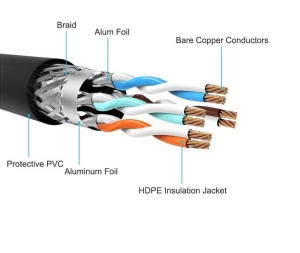

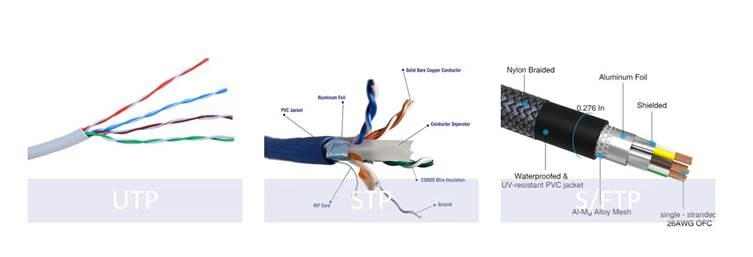

UTP (Unshielded Twisted Pair) cables rely solely on the twisted pair design to reduce interference. While adequate for indoor use in low-interference environments, UTP cables are generally not recommended for outdoor installations, especially near power sources or electrical equipment.

FTP/STP (Foiled/Shielded Twisted Pair) cables include an overall foil shield around all twisted pairs, providing moderate protection against external interference. This configuration reduces signal leakage and improves security but requires proper grounding to be effective.

S/FTP or S/STP (Shielded/Foiled Twisted Pair) cables offer the highest level of protection, with individual shielding for each twisted pair plus an overall shield. This comprehensive approach maintains signal integrity even in high-interference environments, making it essential for industrial settings or installations near high-voltage equipment.

For most outdoor installations, at minimum an FTP/STP configuration is recommended, with S/FTP being preferable for critical network connections or environments with known interference issues.

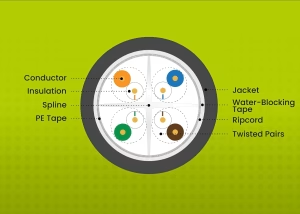

Direct Burial Rating

Standard outdoor cables are not suitable for underground installation; cables rated specifically for direct burial are required. Underground installation provides protection from physical damage and weather but presents specific challenges that necessitate specialised construction.

Cables not rated for burial can be crushed by soil pressure, resulting in internal wire damage and network failure. Ground moisture conditions differ from rain exposure and can cause corrosion in cables not designed for continuous soil contact. Additionally, freeze-thaw cycles can damage non-burial rated cables due to expansion and contraction.

Direct burial cables feature enhanced resistance to crushing, superior waterproofing (often with flooding compounds to eliminate air spaces), and jacketing materials resistant to degradation from soil chemicals. Some direct burial cables also include rodent protection features.

The failure of non-direct burial cables installed underground can necessitate expensive excavation for replacement. Selecting appropriate direct burial cables initially can save significant time and cost in the long term.

Temperature Rating

Outdoor temperatures exhibit significantly wider fluctuations than indoor environments, imposing additional stress on network cables. Extreme heat can soften jacket materials and affect internal wire insulation, while extreme cold can cause cables to become brittle and susceptible to damage when flexed.

Without appropriate temperature ratings, cables may experience increased signal attenuation at temperature extremes, effectively reducing their usable length. Physical deformation can lead to internal wires making contact and causing short circuits, and thermal expansion and contraction can loosen connections at termination points.

Quality outdoor cables typically operate reliably between -40°F and 167°F (-40°C and 75°C), with industrial-grade options offering even broader operating temperature ranges. When selecting cables, it is important to consider local climate extremes and ensure that the cable specifications exceed these conditions to guarantee year-round reliability.

Maintenance and Longevity of Outdoor Ethernet Cables

Proper maintenance can significantly extend the lifespan of your cables, preventing connectivity issues and reducing replacement costs.

Regular Inspection Routine

Based on how harsh your environment is, establish the frequency at which you will inspect your cables. We recommend:

- Quarterly inspections in harsh environments with extreme weather, high UV exposure, or wildlife activity

- Bi-annual inspections in moderate climates with seasonal changes

- Annual inspections in mild, stable environments with minimal exposure

During inspections, you should check for:

- Physical damage to cable jackets: Look for cuts, cracks, abrasion, or UV degradation that might compromise the cable’s protective layers.

- Connection point integrity: Examine all junction boxes, connectors, and entry points for signs of moisture, corrosion, or physical damage.

- Proper cable support: Verify that mounting hardware remains secure and that cables haven’t begun to sag or experience stress at attachment points.

- Signs of animal or insect activity: Check for evidence of chewing, nesting materials, or insect infestations that could damage cables.

- Water accumulation: Ensure that drip loops are functioning properly and that no standing water has accumulated near connection points or cable runs.

Preventative Maintenance Tasks

Besides inspecting the condition of the cables, some preventative maintenance goes a long way to help extend the cable life.

- Clean connection points: Carefully clean accessible connectors and junction boxes to remove dust, debris, or early signs of corrosion. Use appropriate electrical contact cleaners for connectors.

- Refresh weatherproofing: Reapply weatherproof sealants at building entry points and junction boxes if they show signs of degradation.

- Adjust cable positioning: Reposition cables that have shifted into high-risk areas or that are experiencing stress from improper support.

- Trim vegetation: Keep plants, vines, and tree branches away from cable runs to prevent physical damage and reduce moisture retention against cables.

- Update documentation: Maintain accurate records of your network layout, including cable types, installation dates, and any maintenance performed. This information is invaluable for troubleshooting and future upgrades.

Expected Lifespan and Replacement Planning

So how long should you expect your outdoor ethernet cables to last? Good quality ones should typically last:

- Basic outdoor-rated Cat5e/Cat6: 5-10 years in moderate conditions

- Premium shielded Cat6a/Cat7: 10-15+ years with proper installation and maintenance

- Direct burial rated cables: 15-25+ years when properly installed

Like we mentioned above, these are the most common factors that significantly reduce the lifespan your ethernet cables outdoors:

- Exposure to temperatures beyond the cable’s rated range

- Continuous movement from wind or other physical forces

- Improper installation that creates stress points

- Water infiltration at connection points

- UV exposure beyond the cable’s protection capabilities

Your cables are going to fail or become outdated at some point. That’s just a fact of life. To help you with the replacement process, document your installation thoroughly, including cable routes, junction box locations, and any special installation considerations. Having this documentation is going to make future upgrades or replacement a whole lot easier.

Recommended Outdoor Ethernet Cable Options

For General Outdoor Use

Monoprice Outdoor Rated Cat6

- Category: Cat6

- Features: UV-resistant PE jacket, waterproof design, 23AWG conductors

- Best for: Budget-conscious consumers who still need reliable performance

- Notable qualities: Good value for money while maintaining necessary outdoor specifications

For Direct Burial Applications

Dripstone Cat6 Direct Burial Ethernet Cable

- Category: Cat6

- Features: Double-shielded design, waterproof construction, PE outer jacket

- Best for: High-performance applications requiring maximum protection

- Notable qualities: Supports 1Gbps over 100m, superior shielding for interference protection

For Extreme Weather Conditions

trueCABLE Cat6 Direct Burial, Shielded F/UTP Waterproof, Outdoor Rated Cable

- Category: Cat6

- Features: UV-resistant jacket designed to withstand sunlight, dirt, snow, and moisture

- Best for: Extreme environments

- Notable qualities: Solid bare copper conductors, which offer superior signal strength, conductivity, and flexibility

Factors to Consider When Choosing an Outdoor Ethernet Cable

When evaluating these or other brands, consider these factors:

- Certification and compliance: Look for cables that meet or exceed relevant standards like TIA/EIA-568, ISO/IEC 11801, and have appropriate UL ratings for outdoor use.

- Warranty period: Quality outdoor cables typically come with longer warranties (3-5 years or more), reflecting the manufacturer’s confidence in their product’s durability.

- Conductor gauge: For longer runs, heavier gauge conductors (23AWG or 22AWG) provide better performance than thinner 24AWG or 26AWG options.

- Termination options: Consider whether you need pre-terminated cables with weatherproof connectors or bulk cable that you’ll terminate yourself.

Pre-Terminated vs. Bulk Cable Considerations

For many outdoor installations, especially those requiring weatherproof connections, pre-terminated cables with factory-installed weatherproof connectors can save significant time and potentially provide more reliable connections than field-terminated options.

However, if your installation requires custom lengths or running through conduit with minimal connector clearance, bulk cable may be necessary. In these cases, be sure to purchase weatherproof termination kits designed specifically for outdoor use.

very informative articles or reviews at this time.

Thank you for the compliments. Much appreciated!

There is definately a lot to find out about this subject. I like all the points you made

Thank you, much appreciated! I hope you managed to pick a good ethernet cable for outdoors.

It is possible to speak infinitely on this question.

I’m not sure about infinity but there’s definitely a lot more to cover on outdoor ethernet cables that I couldn’t cover here. Any particular topics you might be interested in?

I like what you guys are up also. Such smart work and reporting! Carry on the excellent works guys I’ve incorporated you guys to my blogroll. I think it will improve the value of my site :).

Thanks for the kind words. Hope it helped you select an outdoor ethernet cable that was right for your needs.

Really insightful post — Your article is very clearly written, i enjoyed reading it, can i ask you a question? you can also checkout this newbies in seo. thank you